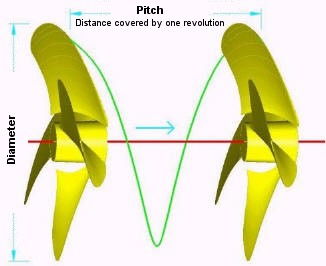

Diameter

Defined as the maximum radius of one blade multiplied by 2.

The diameter of the circle scribed by the blade tips as the propeller

rotates.

General rules:

Diameter usually increases as engine power increases and vice versa. (all

other variables remaining constant)

Diameter increases for slower boats and decreases for faster boats.

figure 1

Pitch

Theoretical definition:

The linear distance that the propeller would move in one complete

revolution through a solid medium not allowing for slip.

Under actual operating conditions, slip occurs as propellers rotate, so

absolute forward movement (actual pitch) is less than theoretical pitch.

Different types of pitch are:

1. Constant (fixed) pitch - pitch is equal for each radius

2. Progressive pitch - pitch increases along the radial line from Leading Edge to Trailing Edge.

3. Regressive pitch - pitch decreases along the radial line from Leading Edge to Trailing Edge.

4. Variable pitch - pitch is different at selected radii

5. Controllable or Adjustable pitch - blade angle is mechanically varied

Pitch Angle (Not to be confused with pitch!)

Angle of the pressure face along the pitch line with respect to the plane

of rotation measured in degrees.

Pitch angle decreases from the blade root to the tip in order to maintain

constant pitch.

Relationship between Pitch & Pitch Angle

Formula: Tan a = Pitch / 2P r

where: a = pitch angle and r = radius and P=Pi (3.14159)

Pitch Line

A line that passes through the Leading Edge and Trailing Edge of a blade

used as a reference for pitch angle.

Propeller Centre Line (PCL)

Linear reference line passing through hub centre on the axis of propeller

rotation.

Propeller Centre Axis (PCA)

Linear reference line that locates the blade on the hub. Perpendicular to

the Propeller Centre Line (PCL).

Blade Centre Axis (BCA)

Linear reference line that indicates propeller rake.

Blade Centre Line (BCL)

Reference line that intersects each cylindrical section at the midpoint of

the blade section width.

Indicates propeller skew.

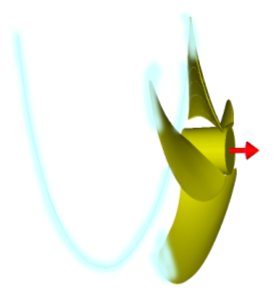

Rake

Propeller blade will slant forward or aft from the Blade Centre Axis

(BCA).

Positive rake - blade slants towards aft end of the hub.

Negative rake - blade slants towards forward end of the hub.

Can be specified in inches at the tip or in degrees.

Skew

Blade Centre Line is curvilinear sweeping back from the direction of

rotation. Contour of the blade is not radially symmetrical about blade

centre axis.

Track

Measurement of axial position of all blades with respect to each other.

Rotation

Right hand propeller rotates clockwise when viewed from astern facing

forward.

Left hand propeller rotates counter clockwise when viewed astern facing

forward.

Twin screw applications utilize both LH (port side) and RH (starboard

side) rotating propellers.

Blade Numbering

By convention the blade located at the position of the keyway is

identified as Blade 1, the next blade in rotation is Blade2 and so on.

Blade Sections

Referred to as Cylindrical Sections.

Hub & fillet area account for about the first 20-30% of the sections.

Blade Section Length & Stations

Section length is the same as blade width.

Each station is expressed as a percent of radius increment ( eg 40 radius

is 40% of the blade radius) .

Blade Section Types

Naca: Symmetrical section. When performance is equal going astern or

ahead.

B.Troost: The most commercially used hydrodynamic profile (airfoil).

Ogival: Used when pressure-cavitation conditions are higher, this section

withstands more pressure before cavitation reaches 3-4%, but is less efficient

than B.Troost.

Hybrid: By combining both the B.Troost and Ogival, this hybrid maximizes the

benefits of both sections.

Airfoil section - resemble traditional airplane wing sections -

i.e. rounded Leading Edge, maximum thickness at about 1/3 length of blade

aft of the Leading Edge.

Supercavitating section - high speed application Sharp Leading

Edge, maximum thickness near Trailing Edge.

Blade Thickness

A blade is thickest at the root for structural integrity.

Within each radial section, the point of maximum thickness may not

necessarily coincide with the midpoint of the chord length.

Blade Thickness Fraction (BTF)

Maximum blade design thickness as extended to the propeller centre line /

propeller diameter. Blades must have enough thickness to achieve desired

sectional shape and provide sufficient strength under loading. Blades that

are too thick produce less propeller efficiency.

Disc Area

Area of the circle scribed by propeller blade tips (P r≤) where P=Pi

(3.14159) and r = radius (1/2

diameter) of the propeller.

Projected Area Ratio (PAR)

Area of projected outline of propeller divided by disc area.

Smallest area ratio.

Developed Area Ratio (DAR)

Similar to Projected Area Ratio if pitch were 0.

Area of blade rotated to 0 pitch divided by disc area.

Most widely used area ratio reference.

Expanded Area Ratio (EAR)

Similar to Developed Area Ratio with sections "unwrapped" from hub.

Largest area ratio.

Camber

Defined as curvature in the mean thickness line of the blade section. Blade Tip

Maximum reach of the blade from the centre of the hub.

Separates the leading and trailing edges.

Leading Edge (LE)

Edge of the blade that first cuts the water.

Trailing Edge (TE)

Edge from which the water exits the blade.

Blade Face (Pressure Side or Pitch Side)

Side of the blade facing toward you while viewing from the vesselís stern.

Blade Back (Suction Side)

Side of the blade facing away from you while viewing from the vesselís

stern. Blade

Root (Fillet area)

The area where the blade attaches to the hub.

Hub

Solid cylinder located at the centre of the propeller.

Bored to accommodate the engine shaft.

Hub shapes include cylindrical, conical, radius, & barrelled.

Keyway

Slender rectangular slot broached into the interior of the hub.

Helps to secure propeller to the shaft and prevent rotational slipping on

the shaft. Cup

Small radius or curvature located at the trailing edge of blade.

Cupping, helps to reduce or delay cavitation.

Helps to reduce slip, thus increasing actual pitch and usable thrust.

Cavitation

Cavitation

Cavitation is the phenomenon of water vaporizing or boiling due to the

extreme decrease in pressure on the forward, or, suction side of the

propeller blade. Cavitation can be caused by nicks in the leading edge,

bent blades, too much cup, sharp corners at the leading edge, incorrect

matching of propeller style to the vessel and engine or, simply high

vessel speed.

Ventilation

Sometimes the term cavitation is used when in reality ventilation is

actually occurring. Ventilation is air from the water surface or exhaust

gases being drawn into the propeller blades which causes the propeller to

over rev and lose thrust. This is the effect that you sometimes feel when

you are running in a following sea in rough weather.

Singing

Some propellers in service produce a high-pitched noise, often referred to

as Singing. This sound typically is a clear harmonic tone much like a

humming or ringing wine glass.

More of an annoyance than anything harmful, the causes of singing are

not completely understood. Many theories have been put forward to

account for the phenomenon of Singing, but it appears to be affected by

critical factors for which the theories make no allowance. For example a

twin-screw vessel has one propeller that sings and the noise is

eliminated just by switching position of propellers. Or a singing

propeller is replaced by an identical spare Propellers which is found to

be silent. Also the lower the number of blades on a prop the less

chances of "singing".

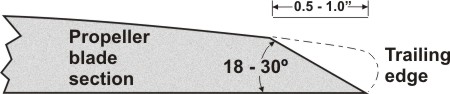

Anti-singing Edge

The singing is a result of propeller diameter and R .P.M. , Boat speed

and Trailing-edge thickness and shape or roundness. In most of the cases

not much can be done on Diameter, Rpm's or speed, but we can modify the

Edge Geometry. This has been the Strategy for all efforts to eliminate

singing.

Most Propeller professionals (and others) are familiar with the

Anti-singing Edge Ė a Chamfering of the Trailing edge, typically on the

Suction side. This shape avoids the creation of curving flow eddies by

cleanly separating the water flow off the blade.

The following graphic shows the Chamfering that goes from 0.5 or 0.4

Radius to the tip of Suction Side.

However the adoption of unduly thin edges can result in erosion or

fracture of the blade near the edges. Anti-sing Edge may be considered

as a last resort to minimize the Singing of an existing Propeller.

Slip

The difference between the theoretical distance the propeller should

travel in one revolution and the actual distance the vessel travels.

For example if you cruise at 2000 rpm and your vessel has a 2:1 reduction

gear, a wheel with 24" pitch, your theoretical speed through the water

should be 19.74 knots (the distance a 24" wheel should move in one hour).

In reality your vessel only does 14 knots at 2000 rpm on a calm day with

no current, the difference is slip.

Article: Propeller Sizing - Have you got the correct propeller?

|